(Part 2)

In Part 2 and last of the series “How SMEs Can Start The Journey Towards Industry 4.0” , find out how manufacturing SMEs can get everyone in the company aboard in their journey towards Industry 4.0; and how SIRIM partners with industries in efforts related to adoption of digitalisation for the manufacturing industry.

How CEO should make decision?

Get your employees onboard. Provide training opportunities early on, so they feel equipped well. Create a technology roadmap, action plan.

How SIRIM can assist?

a. Technology Audit

The audit provides the management of the company with an understanding of their individual strengths and weaknesses as well as potential points for improvement. The outcome of this audit will help the participating company to set up action plans to enhance their productivity, improve their technology management capabilities and move up the value chain. There are many other interesting aspects of the Technology Audit results, findings, recommendations and follow-up activities that companies will find useful in their efforts to become more competitive, innovative and productive. Audit participants will have the opportunity to work with SIRIM in upgrading their technology capabilities, exploring potential improvements such as through mechanisation, automation and upscaling. Participants will also be assessed on their companies’ readiness to undertake R & D and to identify relevant areas of R & D that will benefit the company in the long term.

b. Readiness Assessment

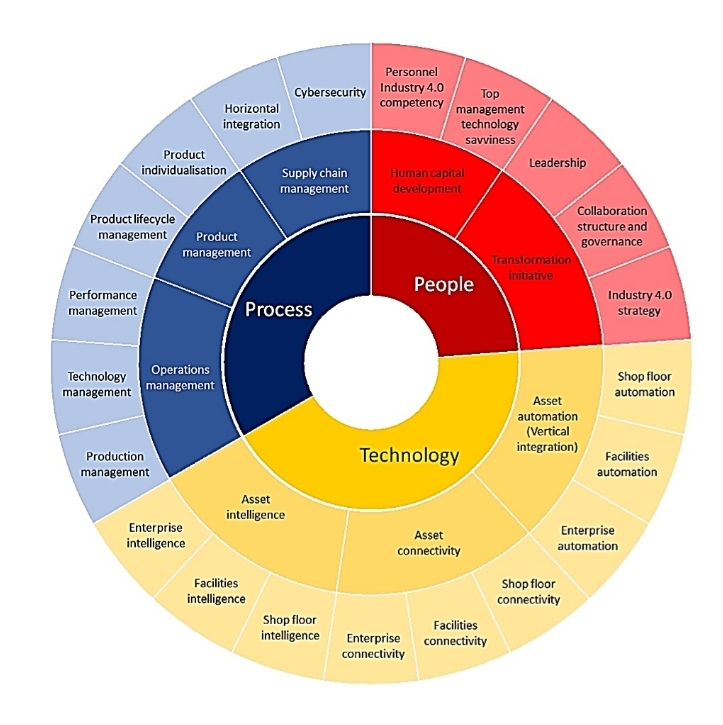

The readiness criteria model consists of three interconnected layers of rings with three shift factors (the core ring). Each shift factor is then divided into thrust (the middle ring) and each thrust is subsequently divided into dimensions (the third outermost ring). The structure of interconnected shift factors, thrusts and dimensions is visualised in the model below:

c. How SIRIM can help SMEs in manufacturing industry to adopt and implement Industry 4.0?

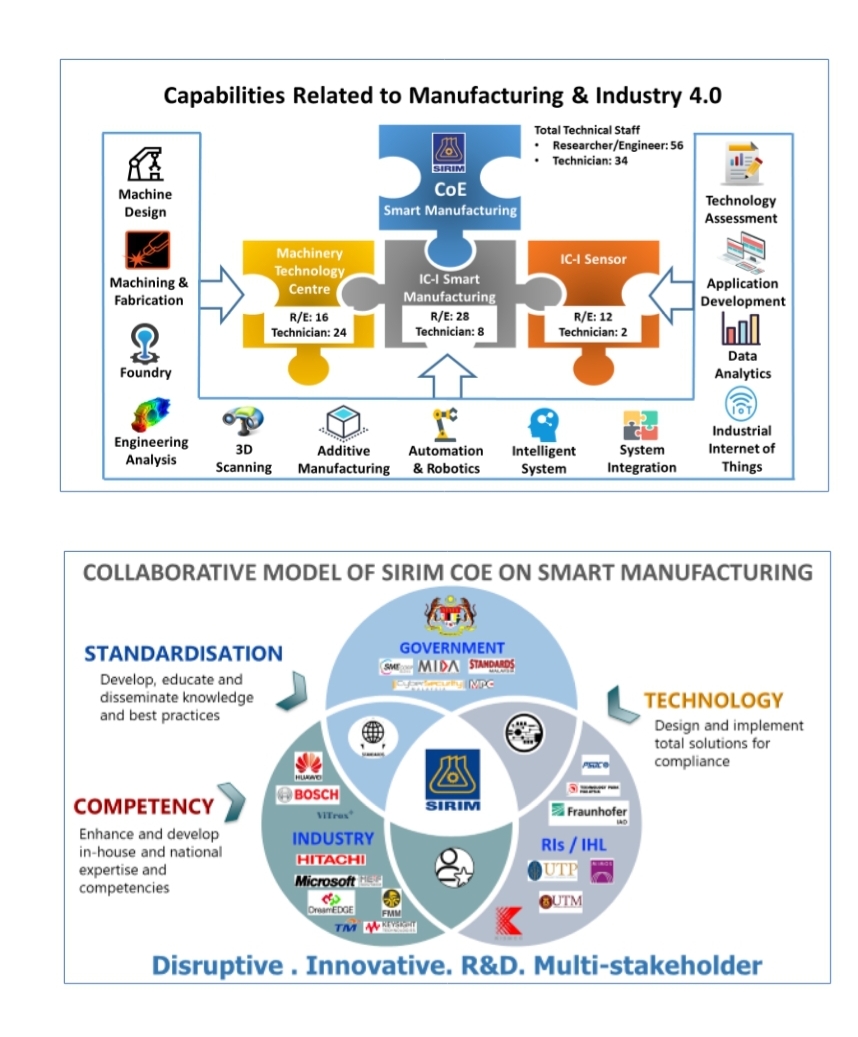

SIRIM has an initiative to transform Malaysian manufacturing SMEs towards Industry 4.0 through its Centre of Excellence (CoE) on Smart Manufacturing. Based on a collaborative model, the operations of the CoE on Smart Manufacturing integrates existing expertise in SIRIM and Malaysia in particular, and among nations generally to develop the technological solutions needed by the Malaysian manufacturing companies to achieve the goals and targets under the Industry4WRD policy.

- In order to achieve these goals, SIRIM CoE on Smart Manufacturing has roles in the following aspects:

Standardisation - developing standards, educating communities and industries; disseminate information on best practices on smart manufacturing.

Talent - training, building and improving national competence in the field of smart manufacturing.

Technology - design, build and provide total solution for manufacturing companies (brownfield) and the start-up or small businesses (greenfield).

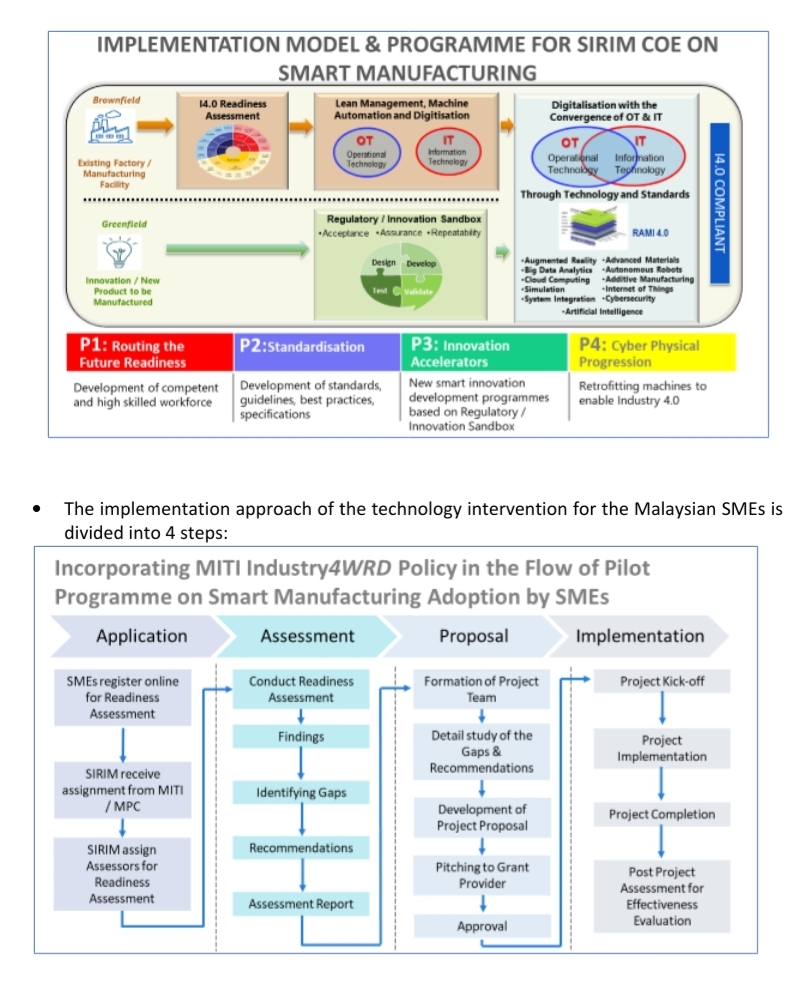

- There are four programmes under this initiative:

P1 – Routing the Future Readiness – Talent Development

P2 – Standardisation

P3 – Innovation Accelerators – Greenfield

P4 – Cyber Physical Progression – Brownfield

Start small win big/ Investment – minimal cost

Start small, grab the low-hanging fruits. It is almost impossible to know budget and time in an environment that is new for you and changing rapidly as part of its nature. Therefore, start small and with short projects. A key to observing success is to break things down into small steps and projects, to gain confidence and build on measurable results.