(Part 1)

Much has been said about moving towards Industry 4.0 (I4.0), the need to move fast, jump into the bandwagon or risk being left out in this digitalisation and automation era. For Small and Medium Enterprises (SMEs), the I4.0 challenges can be overwhelming with more unanswered questions than solutions offered.

In this first part of a two-series article on How SMEs Can Start the Journey Towards Industry 4.0, find out the basic steps that an SME should undertake in moving into Industry 4.0 and how SMEs can benefit from SIRIM’s initiative to transform Malaysian manufacturing SMEs towards Industry 4.0 through its Centre of Excellence (CoE) on Smart Manufacturing.

End-Goal

Each company can start with improvement of its production processes with appropriate operational technologies and lean management concept. From mechanisation to automation and later towards digitalisation, a company must decide what would be its end goal before finding out the technological options available for use. More often companies would need to be convinced or test run solutions before they can run with its full implementation.

- Lean Manufacturing

Companies are recommended to used lean principles and tools to reduce operational complexity and improve productivity. The lean approach provides the foundation for operational excellence by standardising processes, instilling a culture of continuous improvement, reduce waste and empowering workers on the shop floor.

- Digitisation & Digitalisation

Digitising data is an essential prerequisite towards ensuring a smooth digital transformation in Industry 4.0. The process does come with its advantages for companies such as better follow-up of documents, simplified access to content, easier and quicker sharing of documents, reduced search time thanks to a more accurate classification of data, reduced printing costs, increased space (23,000 pages fit in a compact hard drive!) and reinforced security for storage and exchanges.

a) Starting

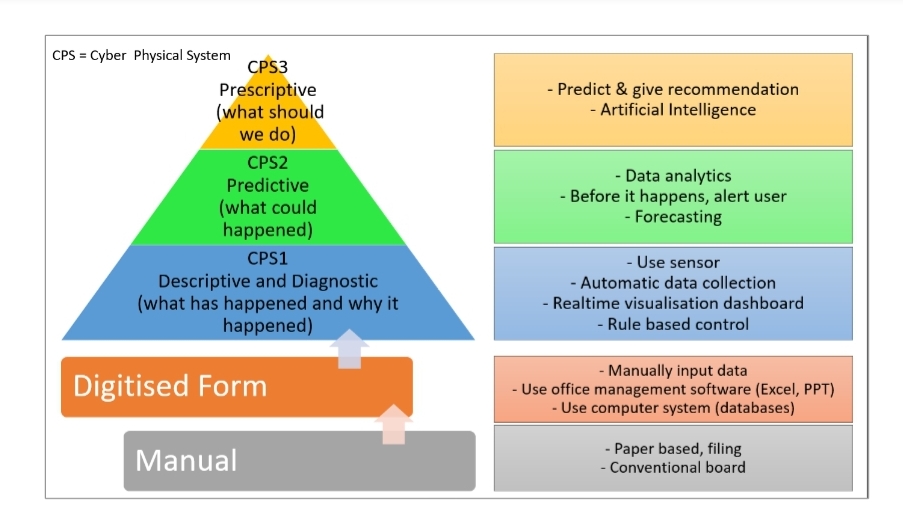

The company can start with transferring the paper-based form into computer-based system such as spreadsheet to do analysis. However, it still requires operator to do data collection, either by manually scanned using measurement tool or download the data from machine.

IIoT

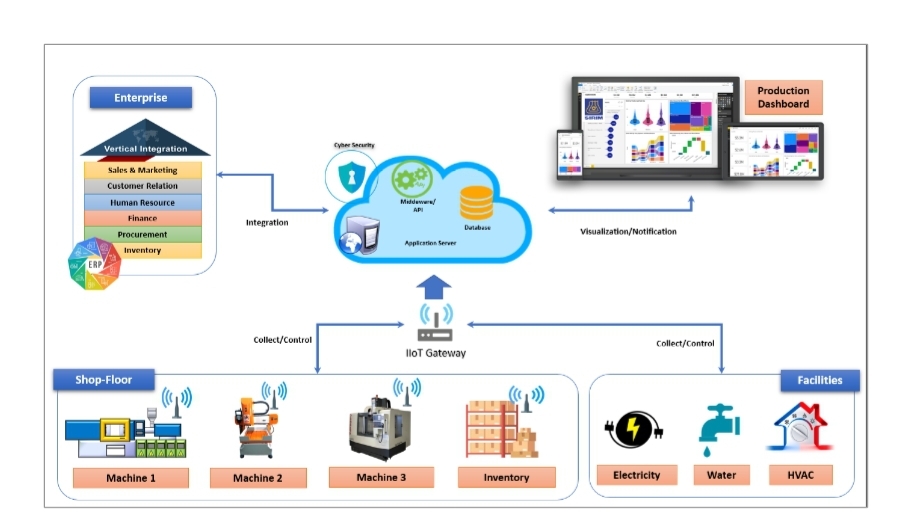

Next step is to automatically do the data collection by installing a sensor that collects the required data. It is known as the Industrial Internet of Things (IIoT). The sensor can be installed at the a location without interfering the production process. It will collect the parameter automatically without human intervention. Some connectivity is needed here otherwise the sensor will act as data logger. Wi-Fi is the reliable technology to be used where the data collected can be directly transferred to in-house data centre/warehouse. This will ensure no human intervention dan real-time data collection.

Cloud

When data is collected real-time, the data will keep growing, at a much larger scale. There is a need to find better methods to process and analyse this data, which will likely require infrastructure upgrades. The company may add more capacity to the in-house data warehouse or power up more servers to cater to the rapidly-increasing analytics requirements. But even with the boost of the on-premise systems, the infrastructure eventually may not be able to keep up. This is where the cloud comes in, or more fittingly, when your big data goes to the cloud.

Cloud is where the company can store and access data or programs over the internet instead of computer’s hard drive. It comes in two basic flavour, public and private, which are the cloud equivalents of the Internet and Intranet. Whether you want to rent a public cloud or store your data at the secure intranet, it is up to the company.

Visualisation/ Descriptive analytics

Begin with the most problematic machine. The analysed data then can be transferred to an electronic dashboard with charts and diagram for better visualisation. Data showed such as overall equipment effectiveness (OEE) which consists of machine availability, machine performance and output, will assist the operation manager to identify problem related to the production. In fact, according to a 2013 study by Aberdeen Group, managers in organisations that use visual data discovery tools are 28 percent more likely to find information that is timely. This is what we called as descriptive analytics or in other word ‘what has happened’.

Diagnostic analytics

This historical data can be measured against other data to answer the question of ‘why something happened’. This is called diagnostic analytics where it involves a possibility to drill down and find out the cause of the problem after the operation manager has identify it.

Predictive analytics

The next step for the company is to do predictive analytics. It will tell the company, ‘what could happen’. Based on the historical data, it uses the findings of descriptive and diagnostic analytics as explain above to detect tendencies, clusters and exceptions, and to predict future trends, which makes it a valuable tool for forecasting.

Integration

While the company is striving to ensure successful digital transformation, the real winning deal depends on the quality and quantity of the data collected. The more relevant the collected data, the more are chances of gaining actionable insights for operation and business expansion strategies. By integrating IoT and ERP (enterprise resource planning), companies can improve data availability, which can lead to operational excellence. The data accumulated due to IoT sensors will be directly fed to the ERP software. Any changes in the process are reported in real-time.

As mentioned above, connected devices can generate a tremendous amount of data. There’s a lot you can do with IoT data, but don’t tackle it all at once. Instead, start with some basic integrations and shoot for an easy win. Grab the data and software that exists in the company. Rather than trying to port all this data into ERP, it will make more sense to identify specific problems.

Integrating IoT and ERP can be a challenge, but it also can be easy. Most ERP systems today have service or interface (Application Programming Interface) that allow for easy passing data between cloud solutions, or from cloud solutions to on-premise ERP systems. This can help make integration much simpler.

Security

In implementing all of those above, don’t forget about security. When you are connected, you are vulnerable to cyber-attack. Make sure the connections are safe, solid and secure. Providing solid gated communications between applications is essential for protecting corporate assets. Develop a policy, strategic plan to assess and monitor your system.

Published by DagangNews.com with consent by Sirim